What We Have Covered in This Article

Last Updated on May 28, 2019 by Editor Futurescope

In a few years to come, we might start printing our foods. Many companies are working to develop top-notch 3-D printers for the food industry and you might start seeing them in your neighborhood very soon. For example, NASA worked with another company situated in Texas to develop a printer that is able to combine powdered food materials with liquids to make delicious foods.

The main goal of NASA when designing the device was to increase stability, nutrition and the safety of food astronauts consume when in space. That will be particularly important during the deeper space missions. They also believe that their new printer might reduce world hunger. Recently, we also observed another printer that was used experimentally in meat production.

The market offers other printing media such as the most recent release, liquid or powdered materials. Liquid chocolate, sugar and pureed food are three other ingredients that people are using to print food items with interesting complex designs and shapes. At times, the use of 3D printers in production of food items is easier than production by hand.

So, how does the 3D printer work to print food?

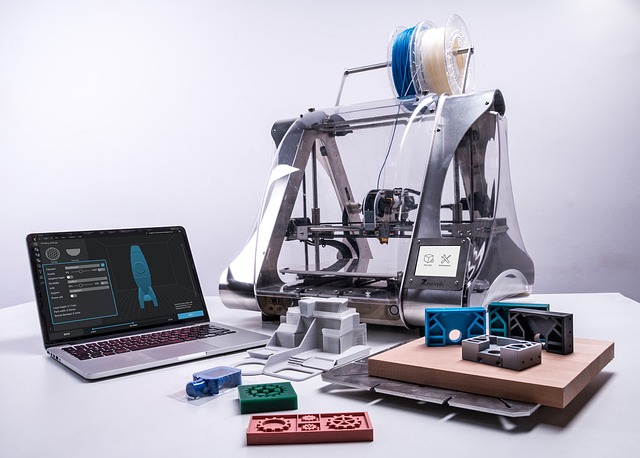

The three-dimensional (3D) printers are devices that make three-dimensional objects. To make the objects, the device deposits layers using a printing medium. Instead of ink, the designers use melted plastic, which solidifies immediately after its release from the machine’s printing nozzle. However, in the food industries, designers do not use plastic. The printers feature food material as the printing medium, not plastic material.

The process of creating an item with a 3D printer begins with the making of a model, object, in a computer-aided design (CAD) program or 3D art program. Many websites are already offering free models and users of 3D printers can download them easily. With that, individuals who do not want to be part of 3D models creation to have fun when using a 3D printer to make their food.

The user has to save the computer codes, which produce the 3D model images as STL files and finally convert them into G codes – the only language a 3D printer understands. The free open source computer programs are able to generate G codes from the available STL files. Some CAD programs are also known to generate the G codes.

A computer uses a USB cable to send the G codes to the 3D printer. In some cases, computers are not important. Some 3D printers feature card readers that can effectively read the G codes from an external SD card. The commonest printing medium among hobbyists is plastic filament. They start by feeding the plastic into the printer’s extruder, which starts by heating and melting it. The printer then releases the liquid plastic through a small opening situated at the extruder’s head to form the needed object. After its release from the printer’s extruder, the plastic solidifies very fast.

The main purpose of the G code is to control the movement of the printer’s extruder head during release of the liquid plastic. The printer has to move the plastic extruder in three axes when printing the object (Z, Y and X). Because the printer lays down the plastic in layers, some people refer to this form of printing as additive manufacturing.

Why people need to produce food with printers?

Three dimensional printing (3D printing) might become an easy way of preparing processed foods compared to the traditional methods. But if the ingredient containers (print cartridges) have to be refilled frequently or the cleaning of the printing parts or ingredient containers will be done by hand, the process of printing foods might be time consuming. If the user has to start by preparing the ingredients or if they need to cook them after the printer has completed the printing processing, the machine is not a good choice.

Children like nice things and therefore, by using pureed vegetables and other food materials to create interesting shapes you will encourage your kids to eat. Such food will contain several important nutrients but might be unattractive to some children. And by allowing your children to make 3D models and print them, you will encourage them to eat more nutritious food.

Businesses may also be able to make unique food designs that will appeal to the public while individuals might start creating pleasant food gifts. Creation of a new food shape is a better way of showing your creativity. Anyone would want to do that.

If you are willing to eat insects, the 3D food printing technology might help you eat more of them. Manufacturers have started offering 3D printers within the price range of small businesses and consumers. Therefore, creative people are working to come up with new printing media and designing new food items. Some of the products are candies, chocolates, sugar decorations and pureed food items. Specialized 3D printers are available for the tasks, but now, most of them are prototypes that a small number of people are using – they are not generally available.

We are likely to witness improvements in this industry. In 2018, the number of prototypes is very high but final versions of printers within the consumer-level price range are minimal. 3D food printing might become a reality in a few years to come.

And because many new printers are entering the market, the manufacturers might reveal more benefits. Advantages and disadvantages of using some printers like Foodini and ChefJet have to be assessed properly, since they are currently unavailable to the public and the manufacturers might modify them before they start selling them commercially.

What nutritionists say

According to nutritionists, you should eat unprocessed food that is rich in nutrients for a healthier life. With that in mind, it can be hard for you to see the purpose of consumer level printers that use unhealthy printing media, unless they are for special occasions. Moreover, some printers might be time consuming and that could negate the benefits of buying one.

Future of cuisine industry

You might be now thinking that using a printer to make foods is strange or silly, but the printers can make the process of food design and production easier. That is particularly true if you consider the restricted capability of the available 3D machines and the amount of time they need to print some types of food. They might provide foods of higher nutritional value.