What We Have Covered in This Article

Last Updated on April 26, 2018 by Editor Futurescope

Today, there is an abundance of modern equipment and devices that are equipped with motion control capabilities. Allowing us to perform tasks that would probably have seemed miraculous for people who lived in the past. Many of these machines, like the numerous assembly and manufacturing equipment we have today. Help us design and produce goods at outstanding speeds and with incredible precision, thus maximizing throughput while maintaining output quality throughout the production process. Others, like microscopes, simply make us better at handling payloads. In this case enable the vital science of microscopy by permitting the operator to precisely position the optical accoutrements that magnify objects under observation.

To give you a better idea about the role that some of these machines and devices play in our daily lives, we’ve compiled the list below.

3D Printers

3D printing has really skyrocketed in popularity in recent years. Thanks to its convenience as an alternative manufacturing method that follows the additive manufacturing model. Typically, 3D printing involves the layer-by-layer application of a building material like polymer, which is deposited on the printing surface via an extruder and a hot end. The extruder and hot end are moved around in 3 different axes by a precision linear stage. Which delivers the payload precisely where it is needed. Because it uses precision motion control, a 3D printing machine is able to manufacture three-dimensional objects in very little time, making it valuable in applications where speedy prototyping or actual product creation is desired.

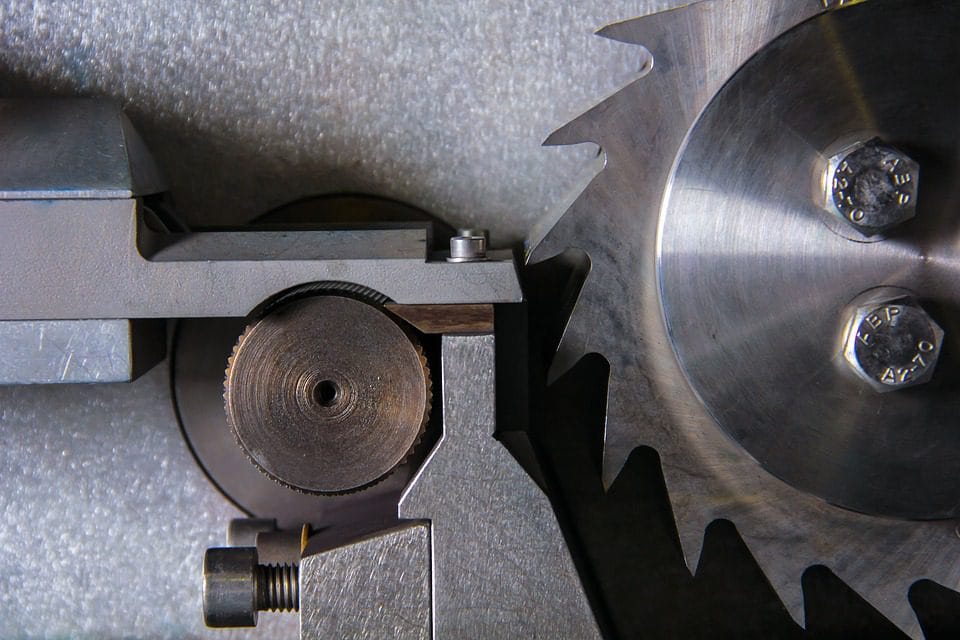

Laser Machining Equipment

Laser machining is a modern form of machining process that can be used to precisely create marks on workpieces or to remove parts of them as part of a subtractive manufacturing procedure. Using highly precise XY stages, a laser machining equipment can focus thermal energy on different surfaces like wood, metal, and plastic—all for the purpose of heating, melting, or vaporizing the material. Laser machining thus have a wide variety of applications. For instance, it can be used to cut pieces off a material for precisely creating components of all shapes and sizes, or it can also be used to burn marks or to etch symbols or graphics on various surfaces. The latter is typically done for labeling or branding purposes.

Automated Liquid Handling Machines

Automated liquid handling is an important technology that is at the heart of many modern life sciences and diagnostics procedures. Because of the scale and complexity of many modern laboratory protocols, it is virtually impractical and impossible to perform tasks. Such as pipetting, transferring, and dispensing hundreds of liquid samples manually. In many high-throughput applications such a genomic sample preparations, aliqutoing, immunoassays, and screenings, it is necessary to process numerous batches of samples all at once. This can only be done with the help of an automated liquid handling machine. Moreover, employing automation will also prevent stress injury and human error among laboratory personnel, who will, incidentally, also have more time on their hands to perform other more important tasks.

Surface Mount Technology Placement Equipment

Printed circuit boards or PCBs are vital in today’s world because they mechanically support and electrically connect the electronic and electrical components in a wide range of consumer and enterprise-class electronics. Basically, PCBs are put together using surface mount technology placement equipment. These machines precisely position and mount electronic components like integrated circuit boards or individual resistors and capacitors onto the printed circuit boards. The surface-mount devices are so small and delicate that the only way they can be mounted precisely at a fast enough pace required by today’s industries with the help of computer-aided pick-and-place machines that use precision motion control systems.

Microscopes

Microscopes are essential in a lot of different fields. They are used in manufacturing for examining the quality and reliability of products, for conducting failure analysis, and for performing counterfeit detection. They are also used in a wide range of scientific fields, including the different branches of biological sciences and earth sciences. Moreover, researchers and scientists also use them in important areas of applied science, including medicine and forensic science. Microscopes depend on the precise positioning of its optical components in order to function properly. For this, it depends on highly accurate linear stages, just like all of the equipment mentioned on this list.

Indeed, the incorporation of highly precise motion components like linear actuators and linear stages into many of today’s modern equipment is critical to their daily operation. What other types of machinery or equipment can you think of?